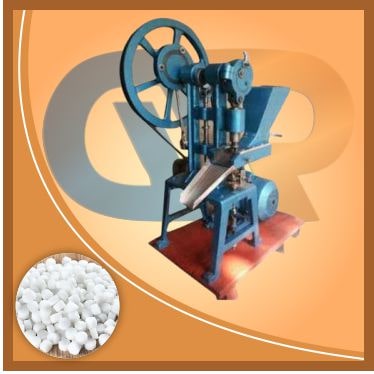

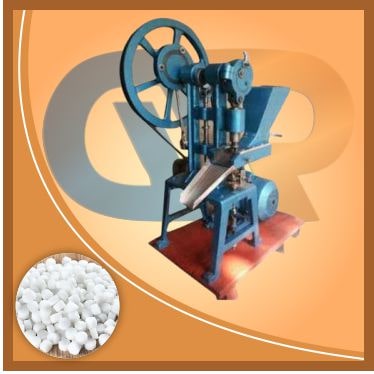

Camphor Tablet Making Machine

Camphor Tablet Making Machine

Camphor Tablet Making Machine

A camphor tablet making machine is a specialized equipment used to produce camphor tablets in various shapes and sizes. These have a compact design and are easy to run and preserve. It comprises various components that work together to create these aromatic wonders.

These machines are perfect for pressing chemical powders, ceramic and camphor powders to convert these into tablets. Camphor tablets are in high demand worldwide because of their versatility and therapeutic properties. For various industries, we are offering our clients a distinguished range of Kapoor making machine.

Applications:

Camphor tablet making machines have versatile applications. These machines can produce other items such as incense sticks, mosquito repellent coils, etc. This flexibility allows manufacturers to diversify and reach a broader market.

Product Description

Armind Industries leads in manufacturing and supplying top-quality automatic camphor tablet making machines in Bihar, including Patna, India. It automates molding and shaping camphor, eliminating the need for manual labor. With this machine, you can prepare a set ranging from 5 tablets to 20 tablets at one time.

Camphor tablet making machines vary in size and capacity, suitable for both small and large-scale production. It is important to choose a machine that aligns with the desired production volume and requirements.

What are camphor tablets?

Camphor tablets, those small white blocks that carry a distinctive scent, have been around for centuries. These tablets derive from a crystalline substance sourced from the wood of the camphor tree. These tablets used in religious ceremonies have aromatic and medicinal properties.

Cost of camphor tablet making machine

Investing in a camphor tablet making machine a prudent choice for those starting or expanding their manufacturing business. The camphor tablet making machine cost varies based on features, capabilities, and manufacturer.

Where to buy camphor tablet machine

Considering venturing into camphor tablet production or upgrading your line? Investing in a automatic camphor tablet making machine is a wise choice. Armind Industries is leading camphor tablet making machines manufacturer in Bihar, Patna, India. With years of industry experience, we give high-quality machinery designed to meet camphor tablet manufacturers’ unique needs.

Skilled engineers and technicians design and produce advanced machinery that is at the forefront of technological progress. We offer camphor tablet making machines at reasonable price without compromise on quality or performance. Our machine is suitable for your specific requirements. Customized options may also affect the overall cost of the machine.

Camphor tablet making machine Procedure:

- 1. Material Preparation: Inside the mixing chamber, the raw material is prepared with additives such as camphor powder, fragrance or coloring agents. Rotating blades mix raw materials and create a homogeneous mixture.

- 2. Compression: After we load the material into the hopper, the machine heats and melts it. High pressure rollers force the molten camphor into the molding section and compress it into tablets. It molds tablets into rectangular or cylindrical shapes as required.

- 3.Drying and Packaging: After compression and molding, the drying unit is used to cool tablets and enhance their stability and prevent breakage. The unit uses heat or airflow to remove the remaining moisture and harden the tablets. After cooling and solidifying, we remove the camphor tablets from the mold using ejection pins. We then collect these ejected tablets for packaging and distribution.

- 4. Packaging: Finally, the produced camphor tablets undergo packaging. The packaged camphor tablets are now ready for sale and distribution.

| Product Generic Name | Camphor Tablet Making Machine |

|---|---|

| Minimum Order Quantity | 1 Piece |

| Brand Name | Customized |

| Machine Type | Manual / Automatic |

| Usage/Application | For Making Camphor Tablet |

| Body Material | Iron |

- (1). Increased efficiency and productivity: Camphor tablet making machines produce large quantities of tablets in less time than traditional methods. It enables manufacturers to meet high consumer demand without compromising quality.

- (2).Consistent Quality: The automatic camphor tablet machine ensures consistency in size and density of the tablets. It forms each tablet with precise measurements and compression techniques compared to manual production. This eliminates variations for a superior, uniform product meeting customer expectation.

- (3).Cost-effectiveness: Requiring minimal human intervention, these automatic camphor tablet machines cut labor costs. It optimizes raw material usage, reduce wastage, and saves resources in the long run.

- (4).Improved Safety: Manual production often has a risk in workers’ safety because of hazardous materials. Automatic camphor tablet machines decrease these risks in the entire production. These make sure a safer working environment without exposure to harmful substances.

- (5).Versatility: Camphor tablet making machines offer production versatility. We can adjust them for various tablet sizes and densities to meet diverse market needs. This flexibility enables manufacturers to adapt to changing industry trends and consumer preferences.

- (6). Time Saving: Manual molding and shaping camphor tablets is time-consuming. A camphor tablet making machine making it efficient and time saving.

- (7). Minimal Waste: The automation reduce wastage by controlling raw material quantities for each tablet.

Conclusion

Camphor tablet making machines have transformed the camphor tablets’ manufacturing industry. These machines offer consistent quality control and increased productivity. With their advanced features and streamlined processes, these machines ensuring efficiency, consistency, and cost-effectiveness. The rising demand for camphor tablets expects exciting trends and innovations in future camphor tablet making machine technology. Contact to Armind Industries to buy fully automatic camphor making machines in Bihar, Patna, India.