Wire Nail Making Machine

Wire Nail Grinder Machine

Wire Nail Polisher Machine

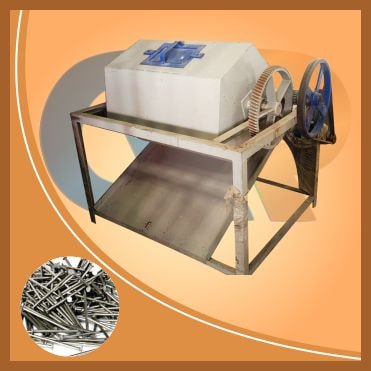

Wire Nail Making Machine

A wire nail making machine is a mechanical device used for nail production from raw materials such as metal wire. Wire nail machine crafts high-quality Nail of various sizes and designs from wire coils. These machines automate the wire nails production and ensuring consistency in nail quality.

These high-speed automatic wire nail making machines have revolutionized the nail manufacturing business by increasing production capacity.

How Does wire nail machine Work?

A wire nail machine includes a wire stand, wire feeder, cutter, gripper die, and a point roller. The wire stand holds the wire coil, feeding it into the machine. Wire feeder feeds the wire to the cutter for efficient nail production. The cutter cuts the wire to the desired length, creating individual nail. Gripper die holds the nail while the point roller shapes the tip.

Product Description

Armind Industries is the manufacturer and supplier of best quality wire nail machine in Bihar used to make good quality nail.Wire nails play a vital role in construction and serving as a fundamental ingredient in various structures.

Wire nail making machines are suitable for both large-scale and small-scale nail manufacturing businesses. Adjust machine settings to produce nails of different lengths, thicknesses, and head shapes to meet specific customer requirements.

The demand for efficient and high-quality nails has led to the growth of manufacturers in wire nail making machines. Armind Industries is a renowned manufacturer and supplier of wire nail making machines in Patna. With extensive industry experience, they offer high-quality machines meeting construction industry requirements.

Models of Wire Nail Making Machine:

There are different machine models that offer different production capacities. Entrepreneurs can select the machine to suit their production needs and budget. The market’s demand for quality nails is driving the increasing need for efficient and reliable wire nail making machines. These machines help streamline the production, saving both time and labor costs.

- (1). Arm 01: This is the basic machine uses wire of 1.2- 2MM thickness and 18 to 14 SWG diameters. It produces ½ to 1.5 inches and 12 to 38MM thick nail. With 1.5HP power motor, it produces 400-450 nails per minute. This basic model weighs around 200KG, ensuring a balance of power and portability.

- (2). Arm 02: This machine uses wire of 1.6- 2.6MM thickness and 16 to 12 SWG diameters. It produces ½ to 2 inches and 12 to 50MM thick nail. With 1.5HP power motor, it produces 300-350 nails per minute. This model weighs around 400KG, ensuring a balance of power and portability.

- (3). Arm 03: This machine uses wire of 2- 3.7MM thickness and 14 to 9 SWG diameters. It produces 1 to 3 inches and 25 to 75MM thick nail. With 3HP power motor, it produces 225-275 nails per minute. This machine weighs around 1100KG, ensuring a balance of power and portability.

- (4). Arm 04: This machine uses wire of 1.2- 2MM thickness and 18 to 14 SWG diameters. It produces 1 to 4 inches and 12 to 38MM thick nail. With 5HP power motor, it produces 400-450 nails per minute. This model weighs around 1500KG, ensuring a balance of power and portability.

- (5). Arm 05: This machine uses wire of 3- 5MM thickness and 10 to 6 SWG diameters. It produces 1 to 5 inches and 35 to 125MM thick nail. It produces 125-150 nails per minute, having 5HP power motor with 3 Phase. This model weighs around 2200KG, ensuring a balance of power and portability.

- (6). Arm 06: This machine uses wire of 4- 6MM thickness and 8 to 4 SWG diameters. It produces 2 to 6 inches and 50 to 150MM thick nail. It produces 110-125 nails per minute, having 7.5HP power motor with 3 Phase. This model weighs around 2500KG, ensuring a balance of power and portability.

Machine required to set up a nail manufacturing plant:

There are three types of machines.

- (1). Nail Making Machine: A nail making machine is the heart of a nail manufacturing plant. It shapes and cuts the wire into nails with varied sizes and configurations. These machines come in various sizes and configurations to cater to different types and sizes of nails. The nail making machine ensures high production capacity and precision in nail production.

- (2). Polishing Machine: After nail formation, a polishing machine enhances their look and removes imperfections by smoothing the surface. This gives a shiny finish to wire nail.

- (3). Grinding Machine: A grinding machine is used to sharpen the nail to give it a specific shape according to the need.

Where to Buy wire nail Manufacturing Machine

To start your own wirenail manufacturing business, need to find the right wirenail manufacturing machine. For starting or upgrading your existing business, Armind Industries offers a perfect solution for you. We fulfil your wirenail manufacturing machine needs with years of experience and a proven track record in India. Contact us for nail making machines cost. Machines are available in a wide range to suit different requirement.

| Product Generic Name | Wire Nail Making Machine |

|---|---|

| Minimum Order Quantity | 1 Piece |

| Brand Name | Customized |

| Machine Type | Automatic |

| Usage/Application | For Making Iron Nails |

| Body Material | Iron |

Benefits of Wire Nail Making Machines

- (1). Increased Production Efficiency: This machine automates wire nail manufacturing. It boosts production speed compared to manual methods and reducing the time required.

- (2). Consistent Quality: The machine brings consistency in the wire nail. It makes sure uniformity in wire nail size and design and strength of each nail. It results in high-quality wire nails that meet industry standards. Consistency in nail quality is crucial, especially for construction and manufacturing industries. Trust these machines to deliver nails for every task.

- (3).Cost Savings: Automating the nail making procedure with wire nail machines cuts labor costs and minimizes human error. This results in long-term cost savings and boosts overall profitability.

- (4). Versatility: Our machines adapt to your requirements. This machine can produce small wire nails to large structural nail such as common nails, roofing nails, etc.

- (5). User-friendly: We give priority to ease in used to maximize productivity. The wire nail making machines have user-friendly controls for easy setup and functions. It allows operators to use them with minimal training.

- (6). Sturdy and Reliable: These machines endure the demands of the construction industry because of their reliability and durability.

Conclusion

Investing in a nail manufacturing plant can revolutionize in your Nail making business. Each machine plays a crucial role in the Nail production from wire drawing to packaging. Discover a best wire nail making machine manufacturer to set up a nail manufacturing plant. Start your Nail production business in India with Armind Industries.