Manual Paper Plate Making Machine

Single Die Paper Plate Making Machine

Double Die Paper Plate Making Machine

.jpg)

Double Die Paper Plate Making Machine ( Small )

.jpg)

Double Die Paper Plate Making Machine ( Center )

Hydraulic Single Die Paper Plate Making Machine

Hydraulic Double Cylinder Paper Plate Making Machine

Paper Plate Making Machine in Patna

A paper dona plate machine is an equipment designed to automate manufacturing disposable plates. These machines manufacture a large quantity of disposable paper dona plates within a short period. We equip them with advanced technology for cutting paper sheets into precise and desired plate sizes.

If you are considering launching a paper plate making business in India to solve environmental issues. Then Armind Industries invites you to our machinery world to explore our range of machines. Manual and automatic Dona paper plate making machine can solve this problem.

Applications of Paper Plate Production Machine:

The paper plate production machine is crucial for Dona paper plate manufacturing. There is consistent demand of paper plates in canteens, bakeries, street vendors, fast-food centres, hotels, and the hospitality. We used these plates in many events, such as weddings, birthdays, functions, and household use.

Today, people seek substitutes for plastic to tackle environmental pollution in the world. Every nation seeks eco-friendly disposable and biodegradable edible plates. Dona paper plate manufacturing business can be a vital solution of this problem.

Types of Paper Plate Making Machines:

Various paper plate maker machines available in the market:

- (1). Manual Hand Press Paper Plate Machine

- (2). Automatic Paper Plate Machine

- (3). Fully Automatic Paper Plate Machine

- (4). Single Die Paper Plate Machine

- (5). Double Die Paper Plate Machine

- (6). All in One Paper Plate Machine

- (7). 4 Die Paper Plate Machine

Paper plate making machine Cost

Disposable Dona Paper plate machines are the primary need for any production. The paper Dona plate making machine price can vary depending on its capacity, model (manual, automatic or fully automatic). The cost of Dona paper plate machine also depends on its features, power consumption, specification and production capacity. You need to spend more money for a high-speed paper plate making machine with advanced features. The price of the paper plate machine depends upon the number of dies.

Machineries / Equipment used for Dona plate business

There are three types of machines. One is a manual hand press machine , automatic machine and the other is a fully automatic paper plate making machine in Patna. Other necessary equipment includes:

- (1). Paper cutting machine

- (2). Double die press machine

- (3). Packaging machine

- (4). Weighing scale

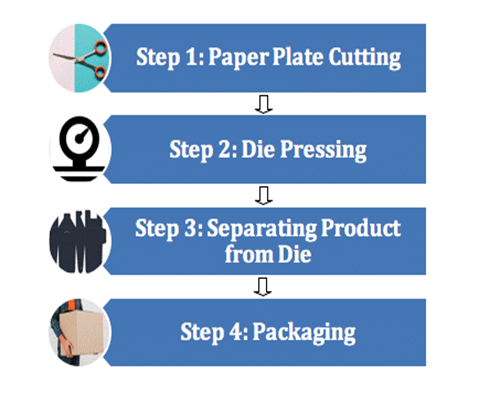

Paper Plate Making Procedure:

Manufacturing paper plates involves just four simple steps:

Step 1: Dona Paper Plate Cutting:

A Paper plate cutting helps to cut the paper into any desired shape or size suitable for making plates.

Step 2: Die Pressing:

Die pressing is holding the paper and polythene sheet together and shape to a plate.

Step 3: Separating Product from Die:

After forming shape, the final product is taken away from the double die press machine.

Step 4: Packaging

At last, we collect, cut, and pack the paper plates for distribution.

Paper Plate Making Flowchart

Scope of paper plate making business

Paper Dona plate machines find their place in a variety of settings. The paper plate business in India is a profitable business. Dona pattal is a cheaper choice than washing dishes. This saves time spent on washing dishes and reduces the labour costs for washing dishes. These paper plates are light, affordable, disposable and also an eco-friendly choice.

Where to Buy Paper Dona Plate Making Machines:

For buying dona plate making machines, essential to choose a reputable manufacturer. Our company is the best paper plate making machine manufacturer in Patna, Bihar. We are the best disposable Dona pattal making machine supplier in India. These machines are used to make paper Dona Pattal plates for home based or large-scale business. Buy paper Dona plate making machine from Armind Industries at reasonable cost in Bihar. We offer after-sales support, spare parts availability, and offer training for operating the machine.

Working of paper plate making machine:

A paper Dona plate making machine includes vital components such as paper feeding mechanism, heating elements, die-set, and control panel. These components work together to make sure a smooth and seamless production.

Dona paper Plate manufacturing procedure:

The paper dona plates manufacturing begins with preparing the paper pulp mixture. The paper pulp mixture comprises paper pulp, water, and other additives. This mixture undergoes heating, shaping, and drying in the paper dona plate manufacturing plant. Selected materials make sure the durability and strength of the final product. Once formed, the plates receive final touches for quality and aesthetics.

Conclusion:

Investing in a paper dona plate making machine can revolutionize your disposable plate manufacturing business. These machines offer a sustainable solution to meet the growing demand for disposable plates. Evaluate your production requirements, choose the right machine to start a small or medium scale business. We meet your paper plate manufacturing needs with user-friendly machines, customization options, and reliable customer support. The paper plate making business in India offers a fertile ground for entrepreneurs with its growing demand and environmental appeal. Contact us today to explore our range of automatic paper plate making machines!

| Product Generic Name |

Paper Plate Making Machine |

|---|---|

| Minimum Order Quantity |

1 Piece |

| Brand Name |

Customized |

| Usage/Application |

For Making Paper Plate and Dona |

| Body Material | Iron |

- 1. Increased Efficiency: These machines automate the entire production of paper plates, streamlining the entire procedure. Reduced manual labour increases production rates without compromising plate quality.

- 2. Cost-effective Solution: You can reduce your production costs after investing in a paper Dona plate making machine . These machines work on low power consumption and need minimal maintenance. It minimizes waste and reducing the cost of raw materials.

- 3. Versatile Plate Size and Design Options: This machine provides flexibility in plate size and design. It can adjust to produce plates of various sizes and shapes according to specific requirements. You can change the plate size to meet your needs.

- 4. Environmental Sustainability: In the contemporary world, environmental sustainability is a major concern. The automatic Dona making machine provides an eco-friendly manufacturing procedure. Unlike plastic, paper plates are biodegradable and easy recyclable.

- 5. Enhanced Product Quality: Using a paper plate making machine makes sure consistent quality in production. These machines give precise cutting and shaping, resulting in uniform plates that meet the highest standards. Automation eliminates human error and reduces defects. Consistent high-quality plate production enhances customer satisfaction and builds a strong brand reputation.