Noodles Making Machine

Noodles Making Machine

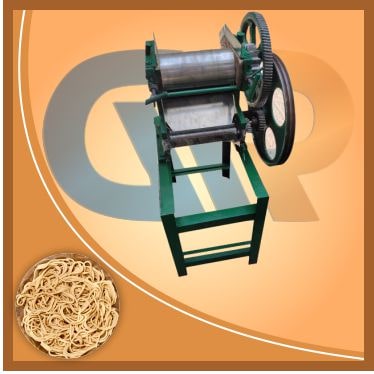

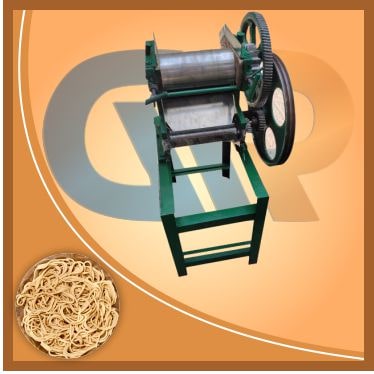

Noodles/ Chowmein Making Machine

In today’s fast-paced world, the demand for instant food products such as Chowmein and noodles is rising. People always seek to reduce cooking time without compromising quality. Noodle making machine play a crucial role in this need. So, restaurants and food processing companies are adopting these Chowmein/noodles machines to meet the growing demand for popular dishes.

A Chowmein making machine is a specialized kitchen appliance that automates the procedure of creating Chowmein noodles. These machines mix, knead and extrude the dough to create perfect Chowmein noodles.

Product Description

noodles making machine | chowmein making machine | Pasta Making Machine

Armind Industries is the leading automatic noodles making machine manufacturer and Chowmein making machine supplier in Bihar, India. We make every machine from high-grade stainless steel. These machines are easy to run, saving time and labor.

Types of Noodles making machine:

- (1). Semi Automatic Chowmein/Noodles Making Machine: The versatility of equipment streamlines noodle and Chowmein production. This machine combines the efficiency of automation with the flexibility of manual procedure. It is ideal for small to medium-scale businesses seeking to boost production capacity.

- (2). fully automatic Chowmein/Noodles Making Machine: These machines are the most advanced choice available in the market. These machines with sophisticated technology can handle the entire production from start to finish. These machines knead dough, cut the noodles and packaging and make sure unmatched efficiency and consistency throughout the procedure.

How Chowmein/Noodles Making Machine Work:

Chowmein/noodles making machines revolutionize the noodle production. These machines automate the entire production and make faster, more efficient and more consistent production. Here’s how they work:

- (1). Mixing Ingredients: The first step in making Chowmein/noodles is to mix the ingredients together. Blend flour, water, and other flavorings using in-built mixers.

- (2). Kneading the Dough: Knead the dough to the right consistency after mixing the ingredients for the perfect texture.

- (3). Rolling and Cutting: The machines flatten the dough into thin sheets and cut the noodles into the desired shapes.

- (4). Cooking: The last step involves cooking the noodles. This involves boiling or frying, depending on the noodle.

Why Start a Chowmein/Noodles Making Business?

- (1). High Demand: The versatility of Chowmein and noodles ensures their popularity among an array of palates. Chowmein / noodles are always in demand at a food stall or a gourmet meal at a fine dining restaurant.

- (2). Profit Margins: The ingredients used in making Chowmein and noodles are cost-effective, allowing for high-profit margins. With careful planning and strategic pricing, entrepreneurs can maximize their profits in this business.

- (3). Low Start-up Costs: Starting Chowmein/noodles making business demands minimal investment compared to other food ventures. It is ideal for entrepreneurs with limited capital.

- (4). Scalability: As your Chowmein/noodles making business expands, you can diversify your product line, introduce new flavors, and franchise. This scalability promotes long-term growth and sustainability in the business.

Components of Chowmein/Noodles Making Machine

- (1). Dough Mixer: This mixes the flour and water to create the dough for making noodles. It is essential to have a sturdy and reliable dough mixer to make sure consistent dough quality.

- (2). Sheeter: The sheeter rolls out the dough to the desired thickness. It plays a crucial role in shaping the noodles and determining their texture. The quality of the sheeter affects the final products consistency.

- (3). Cutting Machine: This part cuts the dough into thin strips, giving you the familiar noodle shape. The precision and efficiency of the cutting machine are essential for producing uniform noodles.

- (4). Boiler: The boiler cooks noodles. Precise temperature control is vital to make sure even cooking and keeping texture.

- (5). Dryer: Once cooked, noodles need drying to drop excess moisture. The machine’s dryer part uses heat for quick drying, crucial for extending shelf life.

- (6). Packaging Machine: After drying, noodles are ready for packaging. The packaging machine seals them in airtight packaging to preserve freshness. A reliable machine ensures noodles reach consumers in perfect condition.

Cost of noodle making machine

The noodle/ Chowmein making machine price can vary on its brand, capacity, features, material and size of machine. These machines come in various models, sizes and specifications. The Cost of noodle making machine depends on the specific need and production scale of the client too.

Where to Buy Chowmein/Noodles Making Machine:

Looking to start or elevate own your noodle or Chowmein business at home? A Chowmein/noodles making machine can revolutionize your kitchen, offering fresh and delicious noodles. For buying the best Chowmein machine at a reasonable price, Armind Industries in Bihar is the right place! We offer high quality and reliable machines to our clients with years of experience in the Industry. Armind Industries Bihar is the go-to source for businesses looking to invest in food processing equipment.

| Product Generic Name | Noodle/Chowmein Making Machine |

|---|---|

| Minimum Order Quantity | 1 Piece |

| Brand Name | Customized |

| Usage/Application | For Making Chowmein / Noodles and Pasta |

| Body Material | Iron |

- (1). Increased Production Efficiency: These machines can produce a large volume of Chowmein and noodles in a single batch. This allows businesses to meet the high demand for these products without compromising on quality. With a higher production capacity, businesses can maximize their market reach and drive revenue growth.

- (2). Consistent Quality: These machines make sure that your Chowmein noodles are of uniform size and texture every time. This consistency is essential for building a customer loyalty and maintaining the brand reputation.

- (3). Time saving: This machine reduces the time required to make Chowmein. It kneads the dough much faster and cuts it into noodles shape much faster than manual methods.

- (4). Cost-Effective: A Chowmein/noodles making machines save money in the long term with minimal maintenance and lower operating costs. The Increased production capacity of these machines can boost revenue, offsetting first investment.

- (5).Versatility: Noodles making machines offer various attachments to create a variety of sizes and textures of noodles. Whether you prefer thick or thin noodles, flat or round Chowmein, the machine can accommodate your preferences.

Conclusion:

Chowmein making machine play a vital role in preparing this beloved dish in the kitchen. Investing in a noodle making machine can revolutionize your noodle/pasta making business. The scope of a Chowmein/noodles making business is vast and promising for entrepreneurs entering the food industry. Increasing Asian cuisine demand and low start-up costs offer entrepreneurs with opportunities to capitalize on Chowmein and noodle popularity. So why wait? Turn your passion for food venture and take your food business to new heights with a Chowmein/noodles making machine.